Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

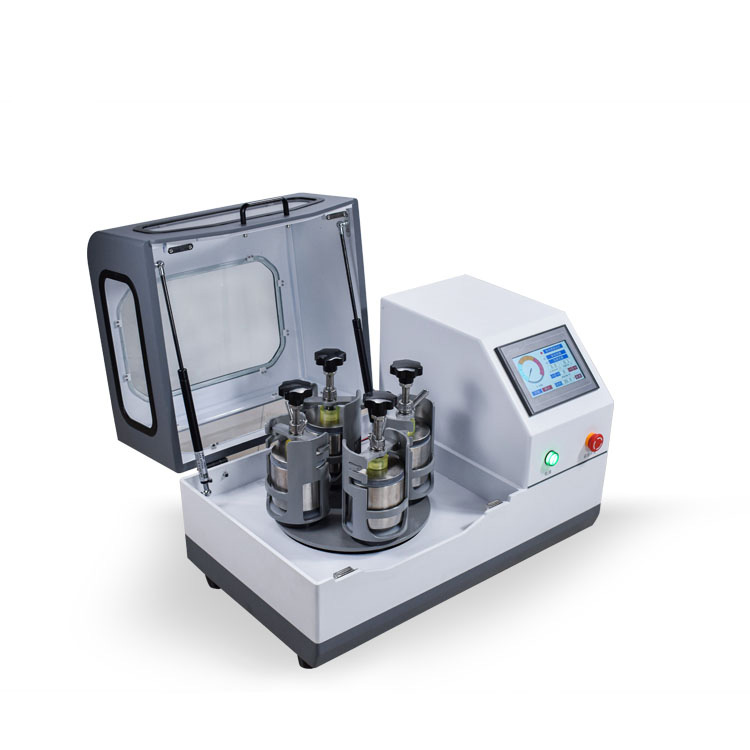

Model:FT-QM

Brand:fengtu

Planetary ball mill Product Introduction:

Application areas: soil, geology, environmental protection, third-party testing, agriculture and animal husbandry, agricultural product quality, resources and environment, soil sample preparation, heavy metal analysis

Application sample characteristics: brittle, fibrous, medium and low hardness, dry or wet grinding

Mechanical processing principle of the instrument: impact force, shear force, friction force

Instrument mechanical processing type: crushing, grinding, mixing, homogenization

Control system: touch screen, wireless remote control

Remote control: Standard wireless remote control, which can remotely control the start, stop, acceleration, deceleration of the grinder and switch between three operation modes (one-way continuous operation, one-way interval operation, two-way alternating interval operation)

Display mode: 7.0-inch color LCD screen, can display, touch operation operation mode, operation time, speed, alternating operation interval

Operation mode: one-way continuous operation, one-way interval operation, two-way alternating interval operation, timed stop

Continuous operation time setting: 0.1~9999.9 minutes

Alternating, one-way interval pause time setting: 0.1~9999.9 minutes

Main disk speed: 50-450min

Grinding jar speed: 100-900min

Transmission ratio (planetary disc, grinding jar): 1:2

Continuous working time (full load): 90h

Emergency stop: The red emergency stop button can cut off the power and stop the machine with one click

Power-off memory function: the time setting before power failure does not need to be reset after power failure

Overload protection function: Yes

Grinding chamber design: sealed and dustproof, with four-way observation windows

Number of samples processed simultaneously: 4

Applicable grinding jars: This machine is a new general-purpose model. It can be used with grinding jars of three specifications: 100ml, 250ml and 500ml. Jars of different specifications can be placed at the same time according to customer needs; they can be diagonally symmetrical (4 grinding jars are a set).

* Maximum injection size: soil 12mm, other 3mm

Grinding jar ball quantity: one third of the jar volume

*Maximum sample volume: two-thirds of the grinding jar volume

Sample size: minimum 0.1um (i.e. 1.0×10mm-4)

Grinding jar material: agate, ceramic, polytetrafluoroethylene, zirconium oxide, polyurethane, stainless steel, nylon, tungsten carbide, cemented carbide, etc. (commonly used agate and zirconium oxide grinding jars)

Grinding ball material: agate, zirconia, stainless steel, ceramic, carbide, silicon carbide, etc.

Grinding ball diameter: 3, 5, 10, 15, 20 mm (configured according to actual needs)

Power port: national standard, European standard, American standard, British standard, etc.

Motor speed, power, voltage: 1400rpm, 0.75kw, 220V±10% single phase, 50/60Hz

Net weight: 80kg

Dimensions (length, width and height): 756*484*488mm

Noise description: 60dB

Protection level: IP60

Planetary ball mill standard configuration: grinder host: 1 set; grinding jar locking device: 1 set of 4; 250ml grinder grinding jar protection device: 1 set of 4; 100ml grinder grinding jar protection device: 1 set of 4; power cord: 1; manual: 1; warranty card: 1; certificate: 1

In canal shipping, visibility is a key factor affecting the safety of ship navigation. Weather conditions such as fog, haze, rain, and snow can reduce visibility on canals, making it difficult for ship drivers to clearly identify waterways, navigation marks, and other ships, increasing the risk of a...

Park air quality monitoring station is an important part of urban garden construction in my country, and its main function is to monitor the concentration and distribution of air pollutants in parks. With the continuous acceleration of urbanization and the rapid growth of urban population, the probl...

In precipitation measurement, while rain gauges and tipping-bucket rain sensors enable convenient and accurate fixed-point observation, their coverage density is generally low in remote areas with sparse human population due to constraints on deployment conditions. This makes it difficult to effecti...

Agricultural meteorological stations is a device used for real-time monitoring of meteorological parameters in the farmland environment, including air temperature, humidity, soil moisture, soil temperature, wind speed, wind direction, rainfall, and light intensity. It features data acquisition, wireless transmission, automatic storage, threshold alarming, and data analysis functions, supporting agricultural management, pest and disease forecasting, and scientific research and teaching....