Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:TP485

Brand:fengtu

one.soil pH test application environment instructions

soil pH test is a soil pH transmitter developed by our company.The transmitter has high accuracy, fast response, stable output, and is suitable for various soil types.It can be buried in the soil for a long time, is resistant to long-term electrolysis, corrosion resistance, vacuum potting, and is completely waterproof.

It can be widely used in the detection of soil pH, pH measurement in precision agriculture, forestry, geological exploration, plant cultivation, water conservancy, environmental protection and other fields.

It can be buried in the soil for long-term dynamic testing.

Stable performance and long service life

IP68 waterproof standard

two.soil pH test technical performance and specifications

1.Technical parameters

| Measurement principle | Electrochemistry (Salt Bridge) |

| Signal mode | RS485 (MODBUS-RTU) |

| Measuring range | 0~14.00(PH) |

| Measurement resolution | 0.01 |

| Measurement accuracy | ±0.1PH, ±0.1℃ |

| response time | About 10s (98% flowing liquid) about 15s (98% still liquid) |

| Shell material | ABS |

| temperature compensation | Automatic temperature compensation |

| Cable length | Standard 5 meters |

| Supply voltage | 12-24VDC (0.4W@12V) |

| Measurement environment | Temperature 0~50℃ (non-freezing), <0.2MPa |

| Waterproof level | IP68 |

| Installation method | Submerged installation, soft soil and mud |

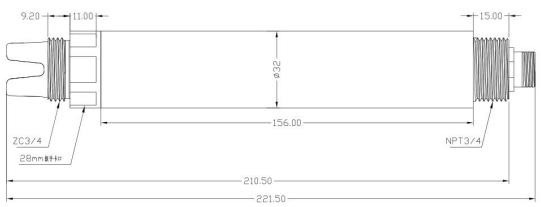

2.soil pH test dimension chart

The sensor connector is M12 aviation plug connector 5-pin female seat

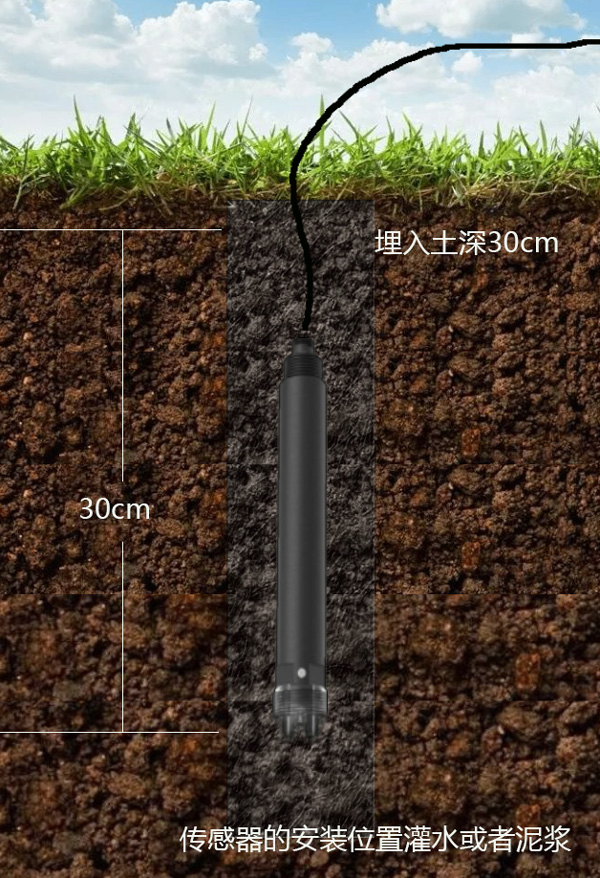

three.soil pH test installation

Installation method

Step 1: Use a soil drill to drill holes at the appropriate location

1.Place the 20mm diameter soil drill vertically on the ground, hold the handle with both hands and press down clockwise to turn it slowly.(Note: Don’t use too much force, and be sure to turn it slowly and several times to prevent the drill bit from wandering and causing the hole to become crooked)

2.Take out the soil auger from the hole and put it into a bucket.Collect the soil in the soil auger into the bucket for the next step and mud.

3.Repeat the above-mentioned drilling and soil removal, and during this process, try to gently put the sensor into the hole (do not touch the device to the bottom with force) to test whether the depth of the hole is appropriate; if there is any lag, Use a soil drill to make corrections to ensure that the sensor is put in and taken out smoothly; until the hole depth is flush with the installation position marked by the sensor, the drilling is completed.

Step Two: Make the Slurry

1.Pick out impurities in the soil, such as stones, grass roots, and hard-to-dissolve soil clods.Grind the soil finely to mix it with the mud.2.Pour in an appropriate amount of water and stir thoroughly until it becomes viscous; loam mud should generally not be thicker than "tahini"; and the mud is complete.

Step Three: Grouting Installation

1.Slowly pour the mud into the hole to about 1/2 of the hole; it can be increased or decreased according to the actual situation.

2.Slowly put the sensor into the hole, slowly turn it in one direction and press down.If the speed is too fast, the air bubbles may not be completely discharged.(Note: Do not pull up the sensor while turning and pressing down to prevent gas from being sucked into the hole again)

3.After the sensor is installed to the correct depth (the zero scale line is flush with the ground), some mud will overflow around the equipment and the grouting is completed.(Note: Remove excess mud beyond 3CM around the sensor to prevent clumping and affecting water penetration)

Step 4: Installation completed

After connecting the power cord and 485 communication line of the equipment, data collection can be carried out 1 hour later.

1.Key points for sand installation

The standard installation steps for sandy soil are the same as those for loam soil.It should be noted that sufficient water needs to be prepared.Before grouting, pour water into the hole and wet the entire wall until excess water appears at the bottom of the hole.Then follow the steps and slowly pour the mud into the hole, probably to 1/2 of the hole.The rest of the installation steps can refer to the installation of loam.

2.Key points for clay installation

When installing the clay, after drilling holes to collect the soil, and cleaning the impurities, soak the clay in water for more than 2 hours to soften the clay and make it easier to form a more uniform mud.After soaking, stir until it becomes thick and ready for grouting.The rest of the installation steps can refer to the installation of loam.

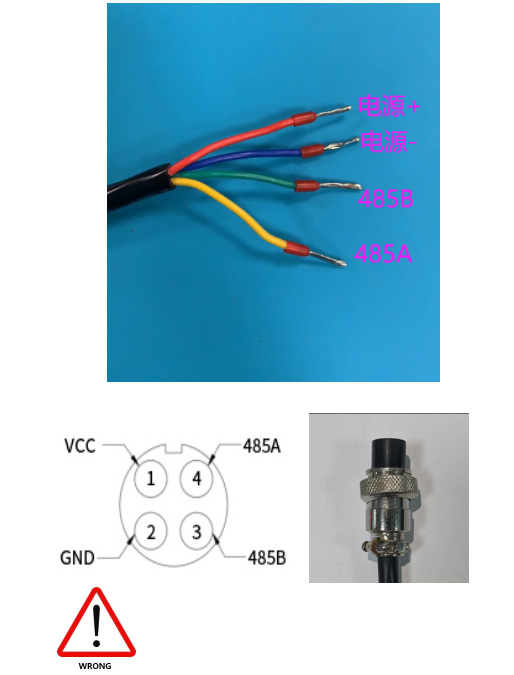

2.Electrical installation

The cable is a 4-core shielded wire, wire sequence definition: red - power cord (12~24VDC)

Blue - Ground (GND)

Green-485B Yellow-485A

The wiring sequence should be carefully checked before powering on to avoid unnecessary losses caused by wiring errors.Note: The color of the cable may vary slightly due to different production batches, please refer to the silk screen printing of the cable.

Incorrect wiring may cause permanent damage to the equipment

Four.soil pH test maintenance and care

1.Use and maintenance

When used for the first time or not used again for a long time, the sensitive bulb and reference junction should be immersed in 3.3mol/L KCI solution for more than 2 hours.

Before use, it should be washed and dried with deionized water (or distilled water) to prevent impurities from being brought into the liquid being measured.1/3 of the sensor should be inserted into the liquid being measured.

The wiring terminal part should be kept clean and dry.The sensor should be cleaned when not in use and inserted into a protective sleeve with 3.3mol/L KCI solution, or the sensor should be inserted into a container with 3.3mol/L KCI solution.

Check whether the wiring terminals are dry.If there are stains, please wipe them with absolute alcohol and dry them before continuing to use them.The sensor should avoid being immersed in deionized water, protein solution, strong acid and alkali solution, and acidic fluoride solution for a long time, and prevent contact with silicone grease.If the sensor has been used for a long time, its glass film may become translucent or have sediments attached.In this case, it can be washed with dilute hydrochloric acid and rinsed with water.

When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by cooperating with the instrument.If the sensor cannot be calibrated and measured after maintenance and maintenance in the above methods, it means that the sensor has failed.Please replace the sensor.

In areas with clean air, the visibility can reach as high as 70-100 kilometers, but air pollution and humidity often reduce it. In areas with haze, fog, smoke, or in the places where sandstorms or forest fires occur, low visibility is extremely dangerous for transportation. Many serious accidents on...

On the stage of nature, agriculture and meteorology are an inseparable pair of dancing partners. The growth, development, yield, and quality of agricultural crops are all directly affected by the weather. Temperature, light, and moisture, these three meteorological elements, constitute the cornersto...

Tea gardens are prone to a variety of pests, including common ones like the tea green leafhopper, tea geometer, tea tussock moth, black citrus aphid, and tea orange mite. The tea green leafhopper feeds by sucking the sap from tender tea shoots, causing leaves to lose greenness, wither, and hinder sh...

Visibility is a crucial indicator in our daily lives and various production activities. From the safe takeoff and landing of aircraft in the aviation field to the navigation of ships in the vast ocean; from the smooth passage of vehicles on highways to the precise analysis of weather phenomena in me...